In this article, I briefly describe how temperature plays a role in preserving food.

Food Preservation

Food preservation involves using various techniques to keep food safe, fresh, and suitable for consumption over an extended period. Since early human history, people have used methods like drying, fermenting, and salting to prevent food from spoiling. In modern times, new technologies such as refrigeration, freezing, vacuum packaging, and the use of preservatives help extend the shelf life of many foods.

The main purpose of preserving food is to slow or stop the activity of harmful microorganisms (like bacteria, yeast, and mold) and to prevent chemical reactions, such as oxidation, that can degrade food quality. Effective preservation not only protects the taste and nutrients of food but also helps to reduce waste and support food availability around the world.

Temperature-Preserving Food

Managing temperature is a key factor in preserving food. By applying methods such as cooling, freezing, or heating, we can effectively slow down or stop the growth of microbes and the chemical reactions that lead to food spoilage. Techniques like refrigeration and freezing help extend freshness by reducing microbial activity, while heating methods, such as pasteurization, work by destroying harmful organisms. Proper temperature control not only lengthens the shelf life of food but also helps retain its safety, taste, and nutritional content.

High Temperature Preserves Food

Using high temperatures is one of the safest and most dependable ways to preserve food. Heat treatment is commonly applied to eliminate microorganisms in foods sealed in cans, jars, or other containers that prevent recontamination after processing. A pressure cooker uses steam under pressure to cook food, making it one of the most effective high-temperature preservation methods, as it can destroy both vegetative cells and spores. This process requires an understanding of heat-resistant microbes, especially spores. Factors such as the rate of heat penetration through foods of varying textures and the size of the containers also play an important role. Canning remains one of the simplest forms of food preservation.

Canning

In canning, the temperature used depends on the acidity of the food—high-acid foods are usually heated to around 100°C, while low-acid foods require higher temperatures, up to 121°C. Despite these high temperatures, canning does not always result in a completely sterile product, as some bacterial spores can survive the heat. One of the most dangerous microorganisms to watch for is Clostridium botulinum, an anaerobic, spore-forming bacterium that can produce a highly toxic and potentially fatal substance if not properly eliminated during processing.

Milk Pasteurization

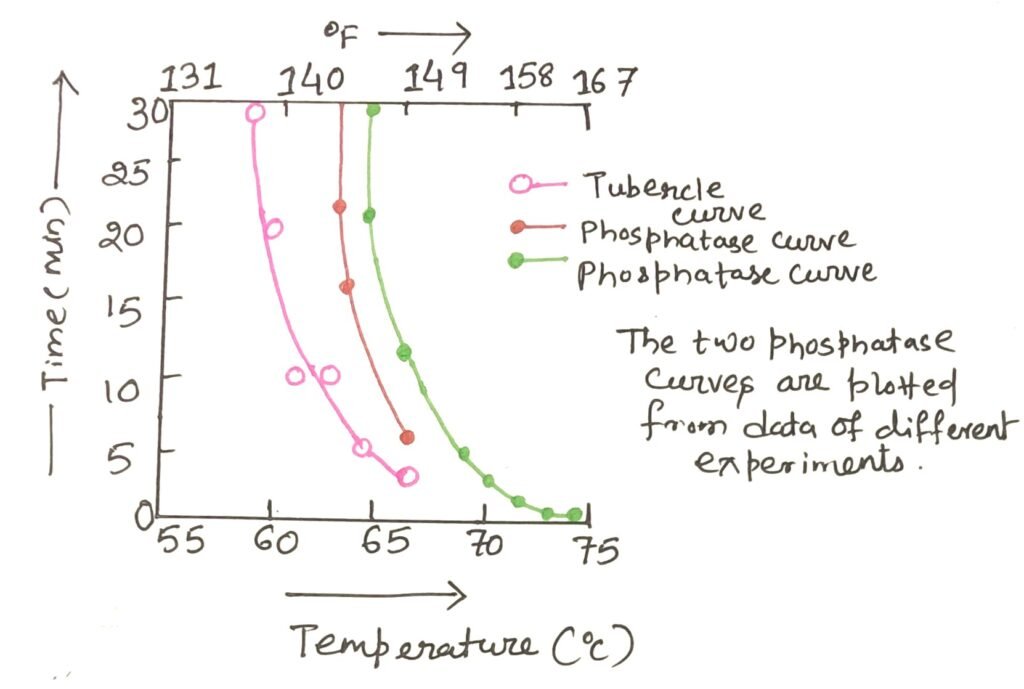

Pasteurization involves heating milk to 145°F and maintaining this temperature for a minimum of 30 minutes. The original time-temperature parameters were based on the thermal resistance of Mycobacterium tuberculosis, then considered the most heat-tolerant milkborne pathogen (Figure 1). This organism is inactivated at 140°F within 10 minutes, leading to a pasteurization standard of 143°F for 30 minutes. Subsequent studies revealed that Coxiella burnetii, the causative agent of Q fever, can survive this treatment, prompting reevaluation of pasteurization standards.

Methods of Pasteurization

Milk pasteurization is achieved primarily through two methods: the Low-Temperature Holding (LTH) method and the High-Temperature Short-Time (HTST) method. The LTH method, also referred to as vat pasteurization, involves maintaining milk at 145°F (62.8°C) for 30 minutes in temperature-controlled, batch-processing equipment. The HTST method utilizes continuous-flow systems that heat milk to 161°F (71.7°C) for a minimum of 15 seconds. In both approaches, the pasteurization equipment must be precisely calibrated and operated to ensure that every milk particle reaches and sustains the target temperature for the designated duration. Post-pasteurization, stringent hygienic measures must be implemented to prevent microbial recontamination. Additionally, the final product must be stored under refrigerated conditions to inhibit the proliferation of heat-resistant or surviving microbial populations.

The Phosphatase Test

Raw milk naturally contains the enzyme phosphatase, which is also found in various body tissues. Proper pasteurization effectively inactivates this enzyme, making its absence a marker for successfully pasteurized milk. The test for pasteurization is based on this principle. In raw milk, phosphatase reacts with a specific substrate as follows:

Disodium phenyl phosphate + phosphatase → phenol + sodium phosphate

Substrate raw milk enzyme products

The quantity of phenol released is determined by adding a reagent that produces a blue coloration when phenol is present. The intensity of the color is compared against standard references to interpret the test results. This straightforward method offers important insights into the adequacy of the milk’s heat treatment.

Sterilization

Commercial milk sterilization techniques entail exposing milk to ultrahigh temperatures for a very short time. The process also includes steps that remove any hint of cooked flavor. The final product is similar to pasteurized milk in taste and nutritional quality. It does not require refrigeration and has an indefinite shelf life.

Aseptic Processing

It is a fairly recent advancement in the food industry. Aseptic processing involves commercially sterilizing food products and packaging them in pre-sterilized containers under aseptic conditions. One key benefit of this method is the ability to use packaging materials other than traditional cans, rendering both economic and consumer-friendly advantages.

Low Temperature Preserves Food

Lower temperature retards the growth and metabolic activities of microorganisms. Refrigeration and freezing preserve food by inhibiting the growth of microorganisms such as bacteria, yeasts, and molds, while also reducing the rate of chemical and enzymatic reactions that lead to spoilage. Modern refrigeration and freezing techniques aid in the transport and storage of perishable foods for a longer time. The cold environment slows down chemical and enzymatic reactions that naturally occur in food, including those that cause ripening, oxidation, and other forms of deterioration. While refrigeration typically slows these processes, freezing can halt them almost entirely by turning water into ice and making it unavailable for microbial activity. As a result, refrigeration helps extend the freshness of food for a few days or weeks, while freezing can preserve it for several months or even longer.

Freezing Techniques

Quick-freezing techniques, which operate at temperatures of -32°C or lower, are considered the most effective because they produce smaller ice crystals and help preserve the integrity of the food’s cell structure. However, it’s important to note that freezing, regardless of how low the temperature is, cannot be solely relied upon to eliminate all microorganisms. The number and types of living and dead microbes found in frozen foods depend on several factors, including the level of contamination in the raw materials, the hygiene standards maintained during processing, and the efficiency and speed of the freezing process.

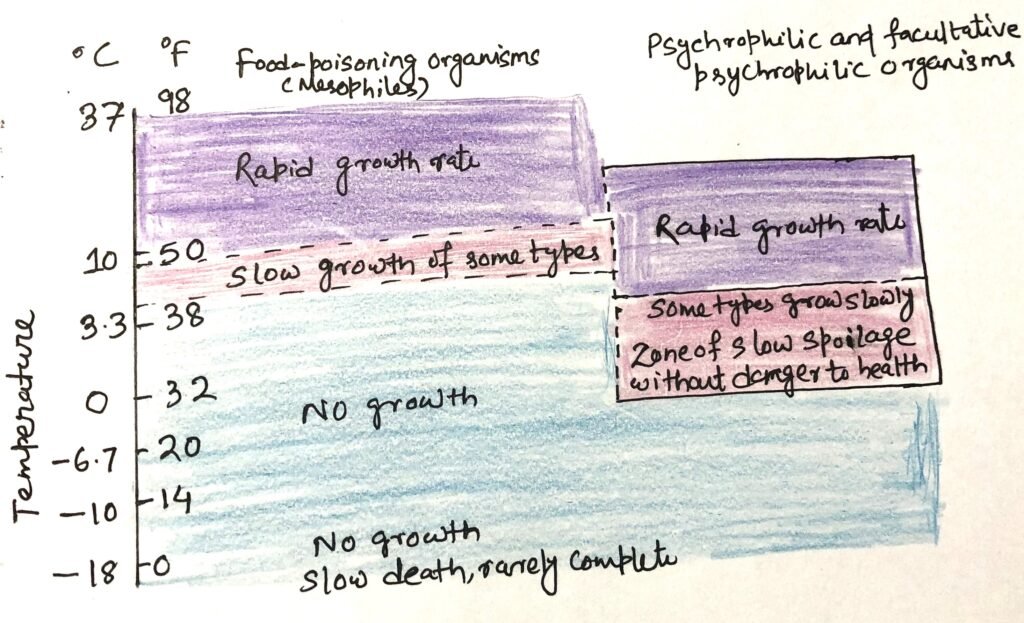

Although the microbial population in most frozen foods tends to decline over time during storage, many microorganisms — including harmful ones like Salmonella — can survive for extended periods at temperatures between -9°C and -17°C. The temperature ranges that support the growth of foodborne pathogens and cold-loving (psychrophilic) microbes are typically illustrated in the figure (Figure 2).

The growing use of precooked, ready-to-eat foods and the widespread use of vending machines that serve perishable items have made it important to gather more information about how microbes grow and survive at low temperatures.

Conclusion

Food preservation uses various methods to keep food safe, fresh, and edible for a longer period. Traditional techniques like drying and salting have been used since ancient times, while modern methods include refrigeration, freezing, and vacuum packaging. The main goal is to slow or stop microbial growth and chemical changes that cause spoilage. This helps maintain food quality, reduce waste, and ensure a steady food supply.

Managing temperature is a key factor in preserving food. By applying methods such as cooling, freezing, or heating, we can effectively slow down or stop the growth of microbes and the chemical reactions that lead to food spoilage.

High temperatures are among the most reliable and safest methods for preserving food, especially when applied to sealed containers like cans or jars to prevent recontamination. Using steam under pressure, a pressure cooker effectively kills both vegetative cells and spores, making it a powerful tool for high-temperature preservation. In the process of canning, the temperature used depends on the acidity of the food—high-acid foods are usually heated to around 100°C, while low-acid foods require higher temperatures, up to 121°C.

Pasteurization involves heating milk to at least 145°F and maintaining this temperature for a minimum of 30 minutes. Milk pasteurization is achieved primarily through two methods: the Low-Temperature Holding (LTH) method and the High-Temperature Short-Time (HTST) method. Commercial milk sterilization techniques entail exposing milk to ultrahigh temperatures for a very short time.

Aseptic processing involves commercially sterilizing food products and packaging them in pre-sterilized containers under aseptic conditions.

Lower temperature retards the growth and metabolic activities of microorganisms. Refrigeration and freezing preserve food by inhibiting the growth of microorganisms such as bacteria, yeasts, and molds, while also reducing the rate of chemical and enzymatic reactions that lead to spoilage.

- Temperature controls microbial growth

- Biochemical and Physiological Characterization of Milk Bacteria

I, Swagatika Sahu (author of this website), have done my master’s in Biotechnology. I have around fourteen years of experience in writing and believe that writing is a great way to share knowledge. I hope the articles on the website will help users in enhancing their intellect in Biotechnology.